Imagine a living breathing building. Not some metaphor – critic’s architecture talk, but actually literally skin that glows with light and eyelight on windy days and just feels existence by what time it is. This is no scene lifted from a science fiction novel. It will happen tomorrow; metal is the humble material that leads the transformation. Forget everything you thought you knew about metal: hard, cold, and impenetrable. The new era brings fresh metal; metal so fresh it bleeds, full of holes telling new stories and fierce, alive experiences tackling the most urgent design monsters of our time. Welcome to the world of custom perforated metal solutions. A single sheet of steel, aluminum, or brass provides a passport for limitless creativity. The result is translation of unique architectural projects from concept to breathtaking reality.

The Poetry of Punches: More Than Just Holes

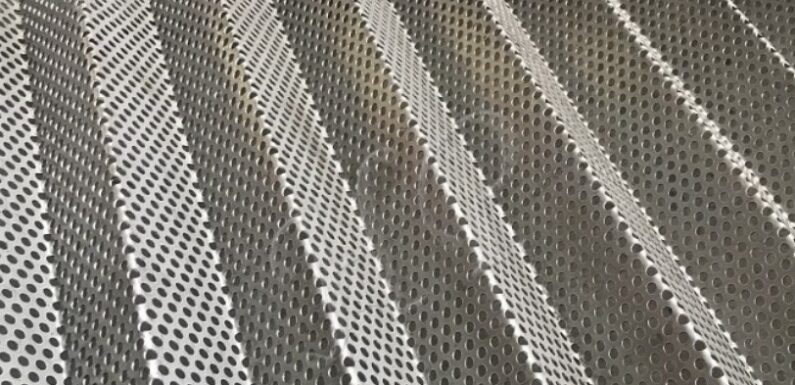

So what’s with this putting holes in metal? On its face, it seems simple enough. But scratch the surface a little and you bump into a level of detail akin to that of a fine art. One does not look at perforated metal as the sum of its solid features but, in fact, delves into the open spaces between them. It’s this fine balance between presence and absence which brings the material its charm. It’s the pattern of these holes: be it a formal line of circles, some free wavy floral sense or a high-tech reproduction of a company’s insignia that finally gives the form its character. Each hole is much like a pixel in an enlarged picture or a note in some visual symphony and dance.

The selection of pattern is the very first and highly crucial artistic decision that any architect or designer arrives at. This is where purpose and beauty begin to mix. An ordinary circular hole pattern may render it a crisp modernist design and fairly uniform strength. But what if a design emulates the shadows of a forest? Or even one that, when viewed from a certain perspective, forms into an image? Here, personalization comes into play. Ready-made choices are great for general purposes, but looking at it from the angle of a project aspiring to uniqueness, only custom-created design can serve this purpose. This punching metal sheet turns out to be a brand, an outstanding mark for the building that narrates a tale even before the first person steps into the building. It is all about making an identity; a visual language completely unique on its own which would be for an industrial headquarters requiring that touch of innovation or for a cultural center which has to depict local heritage.

On talking about the material itself, the perforated metal sheet has been made of more than one base metal, adding to its properties. The contemporary aesthetic of stainless steel suggests an industrial feel that is cool to the touch and represents strength and permanence; qualities associated with time and nature and Corten’s malleability and warm weathering. The last thing it needs to worry about is peeling hundreds of kilograms of paint off tens of thousands of square meters as this simply will not happen. Aluminum is light and corrosion resistant, which also makes it perfect for ambitious structures. Brass or copper adds a little warmth and luxury, its surfaces changing with age to turn into a living façade. The stage is set for architectural poetry through materials carefully chosen in combination with patterns meticulously designed for perforation. All this is made possible in the following superb functional benefits – not proving, after all, that beauty must always be opposite to intelligence in design?

Breathing Buildings: The Functional Magic of Perforated Facades

Okay, so it looks pretty cool. But is it all style over substance? Hardly. The functional benefits of using a custom perforated metal sheet as the skin of a building are so substantial that they often take primacy as the reason for its selection. Think of it as a multi-talented performer, juggling roles in sun control and ventilation and energy efficiency with effortless grace.

The first and utmost is solar shading. With increasing temperatures and awareness regarding the consumption of energy, it becomes a major concern for every large building to manage solar heat gain. This is so because a solid facade bakes in the sun turn it into an oven, and air conditioning costs go through the roof. However, an MLA treated as a perforated metal sheet acts as an advanced brise-soleil. Amorphous enough design may bar high-angle summer sunshine quite substantially so far ingress heat while allowing winter’s low-angle sunshine penetration for passive solar heating. It’s never a panacea: it’s an appropriate response to the climate. The size, density, and placement of the perforations are all variables that can be played with to get the ratio of lights and shadows just right for a given building’s orientation and location.

This leads directly to the concept of the ‘breathing building.’ A solid facade is a sealed barrier, but a perforated one is a filter. It lets air move naturally –on the skin of the building and through it. This could be used to vent hot air from attics or double-skin facades that now overburden mechanical systems and underperform in internal air quality. It shall become more attuned to its surrounding, less a sealed box, and more an interacting organism. Gentle movement of air via the uncountable tiny holes may also assist it with pressure equalization thereby stiffening its demeanor still further. Also, this filtering quality extends to visibility. A metal sheet with holes is a filter with which one can gain security and privacy without those oppressive feelings of a solid wall. Looking from inside to outside, the view may be quite open, especially in case of small ‘holes.’ Sight lines through the façade are minimized, and it’s an excellent solution for applications such as car parks, screening around mechanical equipment, or anywhere you need to obscure the view without totally blocking off.

The acoustic advantages are yet another of the often-overlooked superpowers – sound being a form of energy, similar to when it hits a solid surface which makes it rebound as an echo and reverberation. But placed against the sound waves, the story is different, especially combined with some acoustic backing like rockwool or fiberglass. The waves penetrate the perforations, and the energy is radiated as heat in the backing material. Thus what could be a very noisy and reverberant space-; a railway station, airport, sports hall or busy restaurant-; becomes a much more comfortable and acoustically manageable environment. It’s one way of controlling noise pollution without opting for bulky ugly soundproofing materials. The façade essentially soaks up the sound of the city, creating the calm interior a much quieter sanctuary.

From Sketch to Skyline: The Customisation Journey

The path of a custom perforated metal sheet from inside the mind of a designer to the front of a building is an interesting mix between art and engineering. It’s teamwork that makes clear how such special parts come to life. It often begins not with a CAD file but with a drawing, a photo, or even just an idea. An architect might take inspiration from the scales of a fish, the veins of a leaf, or the steady patterns of old cloth. The task is to turn this natural spark into an achievable hole design.

It is at this point that modern manufacturing steps up to the plate. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software permit patterns of staggering complexity — designs that were totally unfeasible just a few short decades ago. A high-res image can be vectorized, its tones and shades converted into a density map of perforations. The darker areas might have a greater density of smaller holes, the lighter areas seem more open. This is generally referred to as a “halftone” pattern; it allows the sheet metal to behave like a gigantic piece of newsprint carrying an image legible from a distance but falling apart into abstraction close-up. And the possible degree of detail is true architectural artistry.

The customization travels down to every physical attribute of the sheet. The type of metal, its gauge (thickness), in what finish (brushed, mirror, painted pre-weathered), and what size individual panels are all variables. Perforations themselves might be punched in different shapes—round, square, slot hexagonal—and at different angles which in some cases will affect the way light passes through and perceived opacity of the panel. Engineers also work with designers to ensure that whatever pattern is chosen does not compromise structural integrity for the metal. Simulations are run for wind load and stress points including thermal expansion. It goes back and forth; a marriage between a creative vision and technical pragmatism. A building component that is not just a part of the design͏ but becomes the design itself- a fully integrated and functional piece of art specific to its context and purpose.

A Gallery of Holes: Perforated Metal in Action

To truly understand the impact of custom perforated metal, we need to see it in the wild. Let’s take a virtual tour of some hypothetical but entirely plausible architectural projects where the perforated metal sheet is the undisputed star.

Picture a new contemporary art museum in a bustling downtown core. The architect wanted a facade that was both a landmark and a teaser for the art within. They commissioned a custom perforated metal sheet with a pattern derived from a digital analysis of a famous, dynamic brushstroke. From across the street, the building’s facade appears to be a massive, swirling gesture of light and shadow, a piece of art in itself. As the sun moves across the sky, the pattern shifts and evolves. At night, an integrated LED lighting system illuminates the facade from within, making the building glow and the pattern appear to float. The perforated metal sheet here acts as a billboard, a sunshade, and a security layer, all while creating an unforgettable identity.

Now, imagine a high-tech corporate campus looking to foster collaboration and well-being. The design includes a multi-story atrium that connects all the floors. The problem? It’s a giant echo chamber, and the glass walls create a greenhouse effect. The solution? A vast, undulating canopy made from a custom perforated metal sheet with an acoustic backing. The pattern is a subtle, geometric honeycomb, reflecting the company’s focus on data and networks. This canopy floats overhead, filtering the harsh direct sunlight into a soft, diffused glow, while simultaneously absorbing the sound of conversations and footsteps from the floors below. It makes the atrium a usable, comfortable, and inspiring heart for the building, all thanks to the multifaceted performance of the perforated panels.

Finally, consider a boutique retail store on a trendy city street. The owners wanted a storefront that was opaque and mysterious during closed hours but revealed the curated interior when open. They installed a series of large, pivoting shutters made from a heavy-gauge perforated metal sheet. The pattern is a custom logo, repeated across the surface. During the day, when the shutters are open, they frame the entrance and cast intricate shadows on the pavement. At night, when closed and locked, they provide security. But here’s the clever part: when the interior lights are on at night, they shine through the perforations, making the store’s logo visible from the outside and acting as a beacon. The perforated metal sheet provides a dynamic, interactive element that contributes to the brand’s story and the customer’s experience.

The Future is Full of Holes

Looking further forward, the future of architecture is set to become increasingly tied to the nuanced possibilities of components like the custom perforated metal sheet. It is quite sensor fabricated already and converts passive facades into active systems. Think of a perforated metal sheet, where the holes are not fixed positions but form a pattern of louvers that can open and close as per the angle corresponding to the position of the sun, the direction of the wind, or the temperature of the enclosed space — this is what’s called kinetic architecture, and metal punching is an ideal medium for it.

Another exciting frontier is the fusion of perforated metal with solar panel technology. What if the very skin of the building, its decorative and protective perforated metal sheet, could also be a power generator? Thin-film photovoltaic cells behind the perforations can harvest energy from the sun while retaining the aesthetic and functional benefits of the facade. Thus, it becomes not merely a consumer of energy but one of its producers.

This will further drive sustainable action through increased utilization of recycled metals and the adoption of more efficient, waste-minimizing punching processes. The performance design and simulation digital tools of the future will be much more sophisticated, enabling architects to play with variables in real-time and witness the immediate effects concerning light, shadow, ventilation, and structure. Little perforated metal sheet has delivered the expanse of possibilities enjoyed by contemporary architects. It has knocked down the division among interior and exterior among solid and void, among art and engineering. It has provided a voice, a rhythm, and a soul to our buildings. So next time you pass by that building exhibiting so many forms of shadow patterns you will be able to see further. You might be witnessing the beautiful intelligent and endlessly creative world of custom perforated metal solutions.